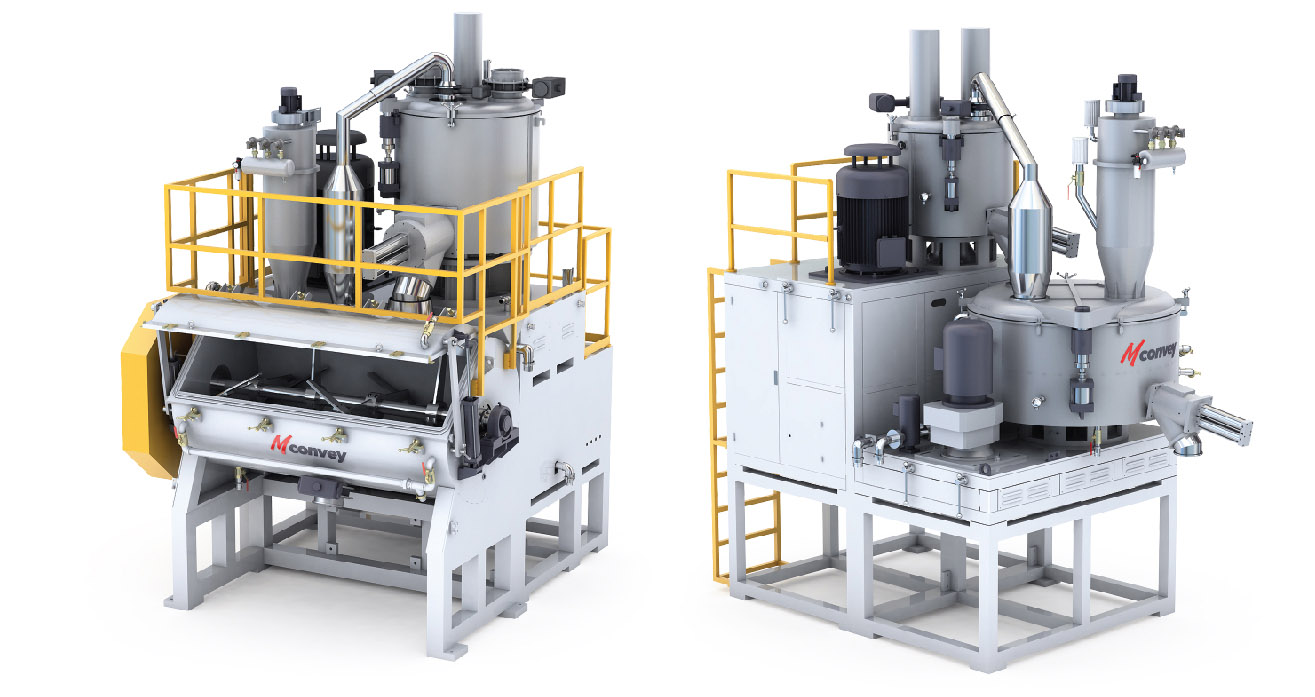

High speed series mixing unit is a hot selling model which is independently developed and manufactured by LIANSU Machinery . It is mainly used in mixing and drying of PVC\PE\PP and other formula, forming and drying before the processing of ABS,PC and hygroscopicity resin , and the mixing process of phenolic resin .The mixing process will achieve the dosing and drying effect by high- speed mixing firstly,and then the material is cooled rapidly by cooling and stirring to prevent caking and material degradation in the high-speed mixing process, while the residual gas in the mixing process is eliminated.

Since 1996, Liansu Machinery has been deeply engaged in the research and development and production of high-speed mixing unit. With 26 years of technology and process precipitation, Liansu has put more than 800 high-speed mixing machine into the market so far. Currently ,the production capacity of the three main models ranges from 600 to 4200kg/H which can fully covering the application requirements of plastic processing .

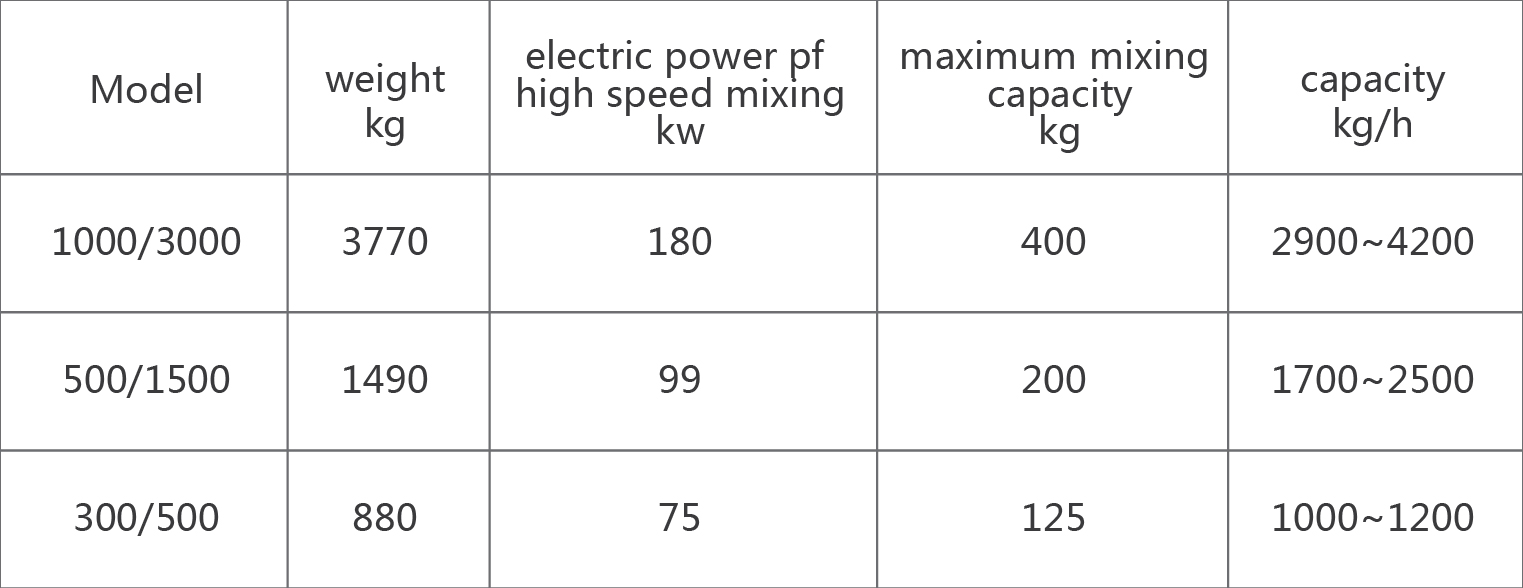

Models are as follows:

technical feature

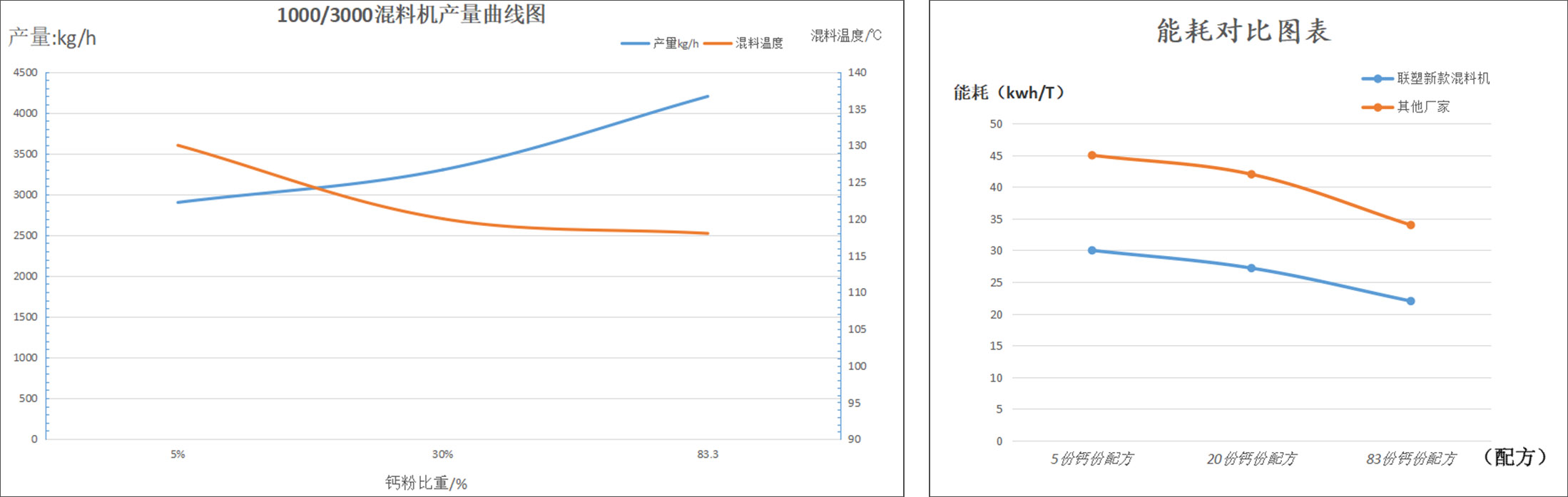

The high speed mixer is driven by super efficient permanent motor ,with energy saving ,strong overload capacity and high efficiency . according to the 1000L high speed mixer, when mixing PVC resin and formula, the mixing volume of a single pot can reach 420KG, the output can reach 2900-4200kg per hour, and the energy consumption is about 32kwh/t

With the high output, low energy consumption also can ensure the high stability of equipment at the same time , mechanical parts of the bearing seat, blade processing technology and rationalization of mechanical structure design is also very important. The unique electrical control system and omni-directional monitoring measures ensure efficient operation and high stability of the unit .

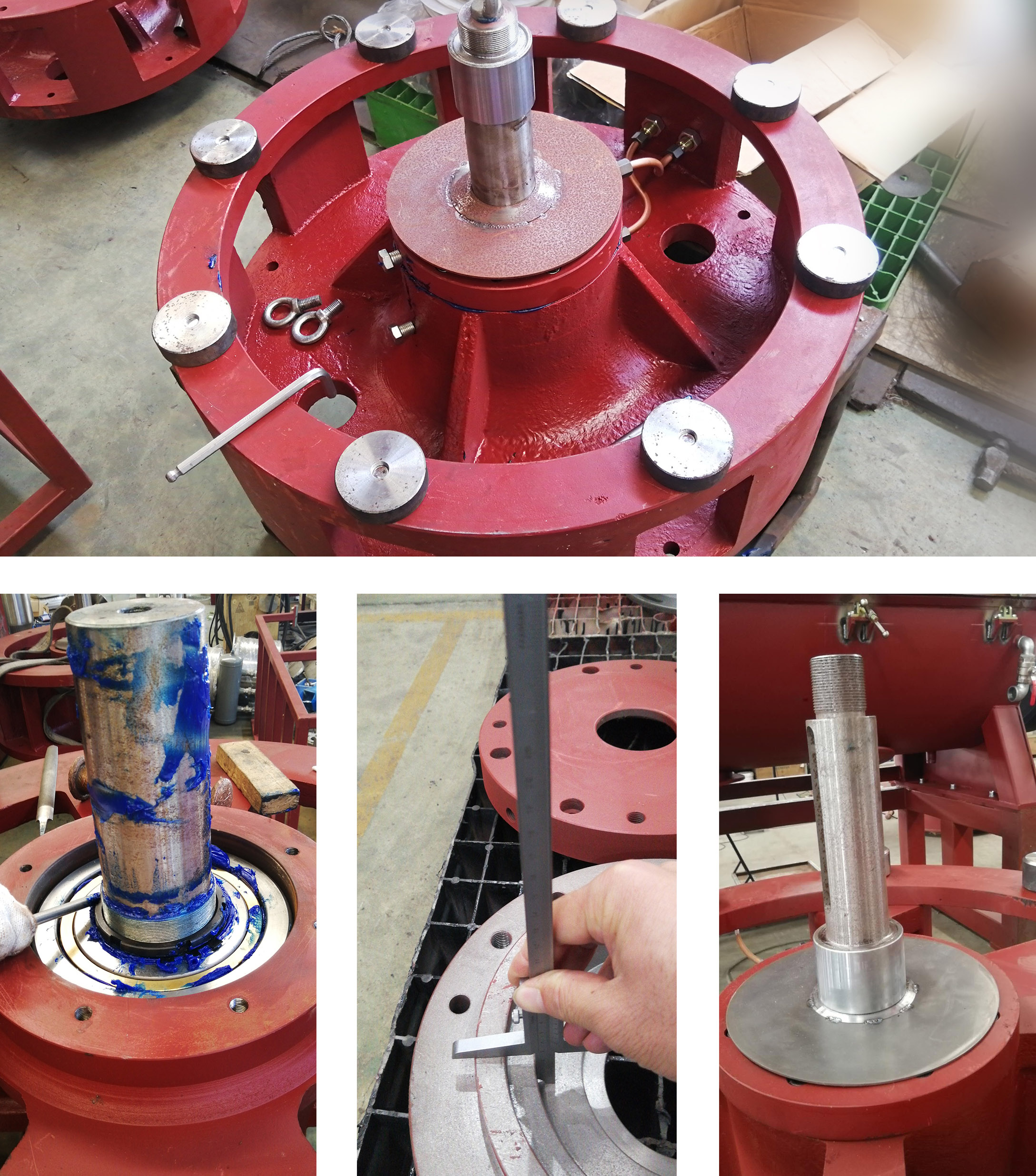

The bearing seat and bearing group of the unit adopts three bearing structure ,which can bear the radial tension and axial thrust of the pulley at the same time, and the triple bearing seal ensures that the powder material does not enter into the bearing group . It will be stable, less vibration and long life when high speed operation.

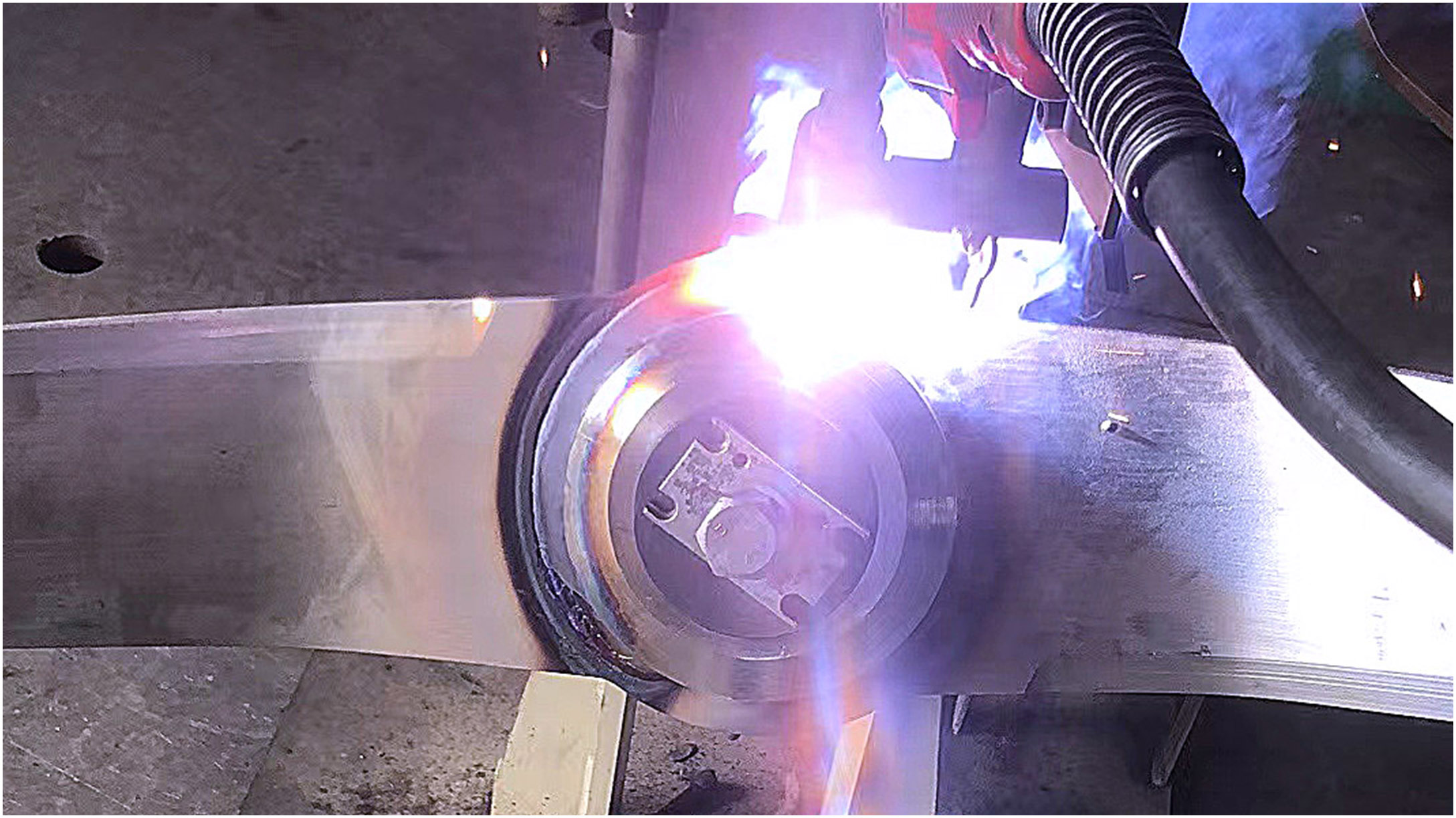

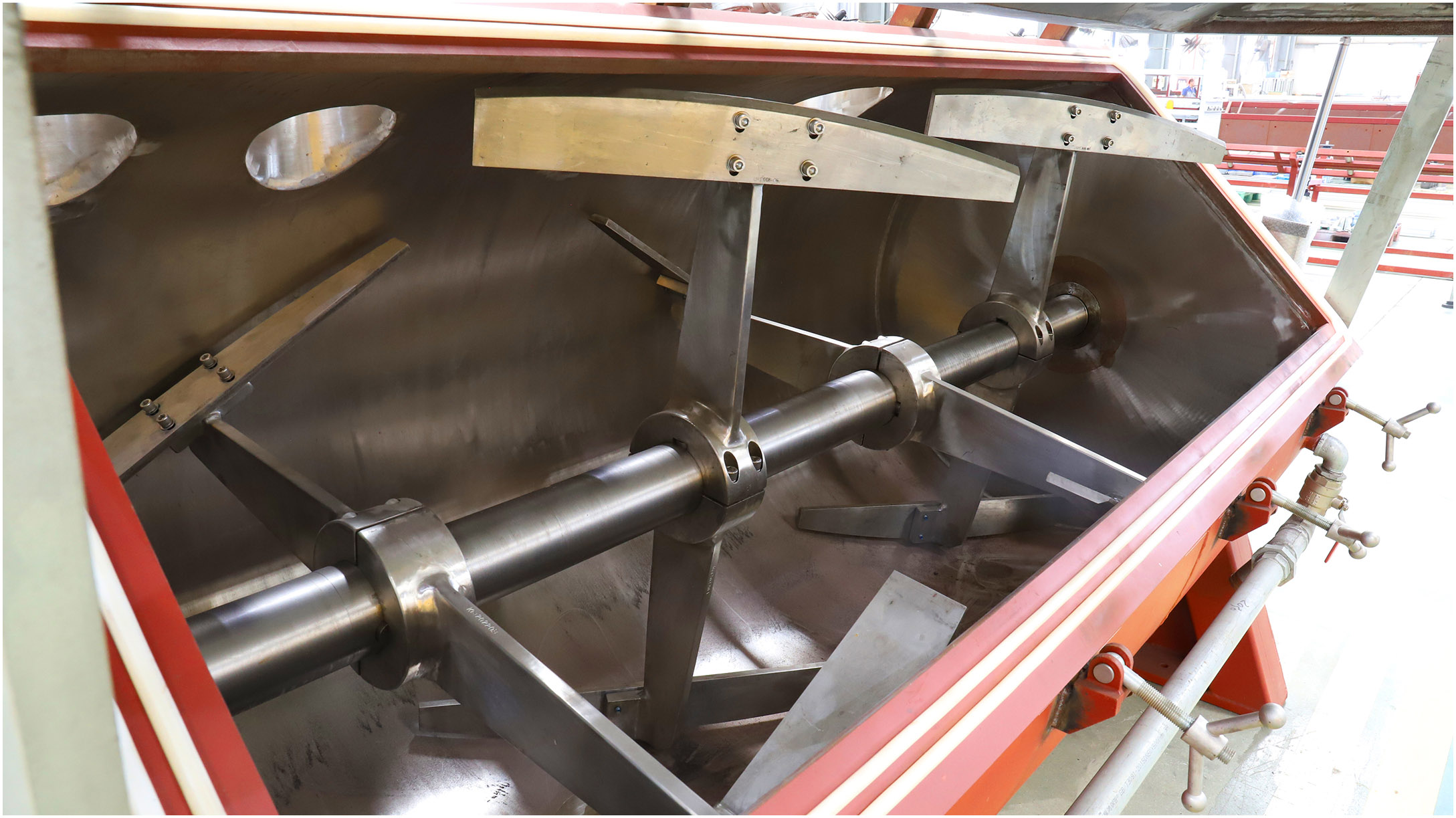

The blade of high speed mixer is welded by whole plate. The welded blade must be corrected by dynamic balance to ensure smooth and quiet operation. The surface of the blade is treated by multi-channel spraying and sintering hardening, which has a long wear resistance and a life of 3-4times than the casing blade. Such as PVC high filling mixed ingredients( 100 calcium carbonate+HDPE) blade service life can reach more than 24 hours.

The high-speed mixer is connected with the cold mixing unit by connecting pipes and equipped with a large area filter and dust removal device, which can accelerate the discharge efficiency of the high-speed mixer while removing dust. Cold mixer ‘s cylinder head and cylinder body adopt labyrinth+forced internal circulation cooling which can fast cooling .

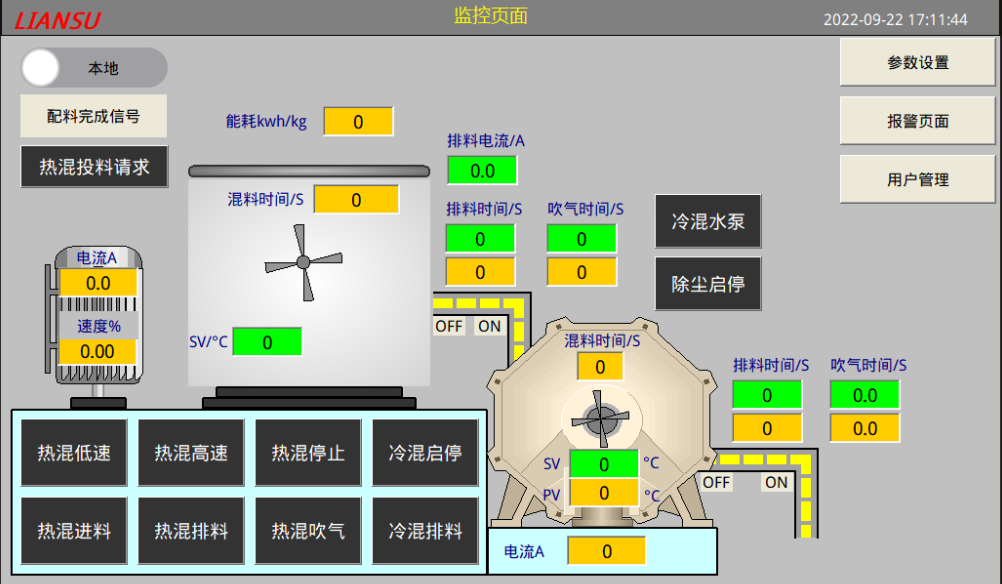

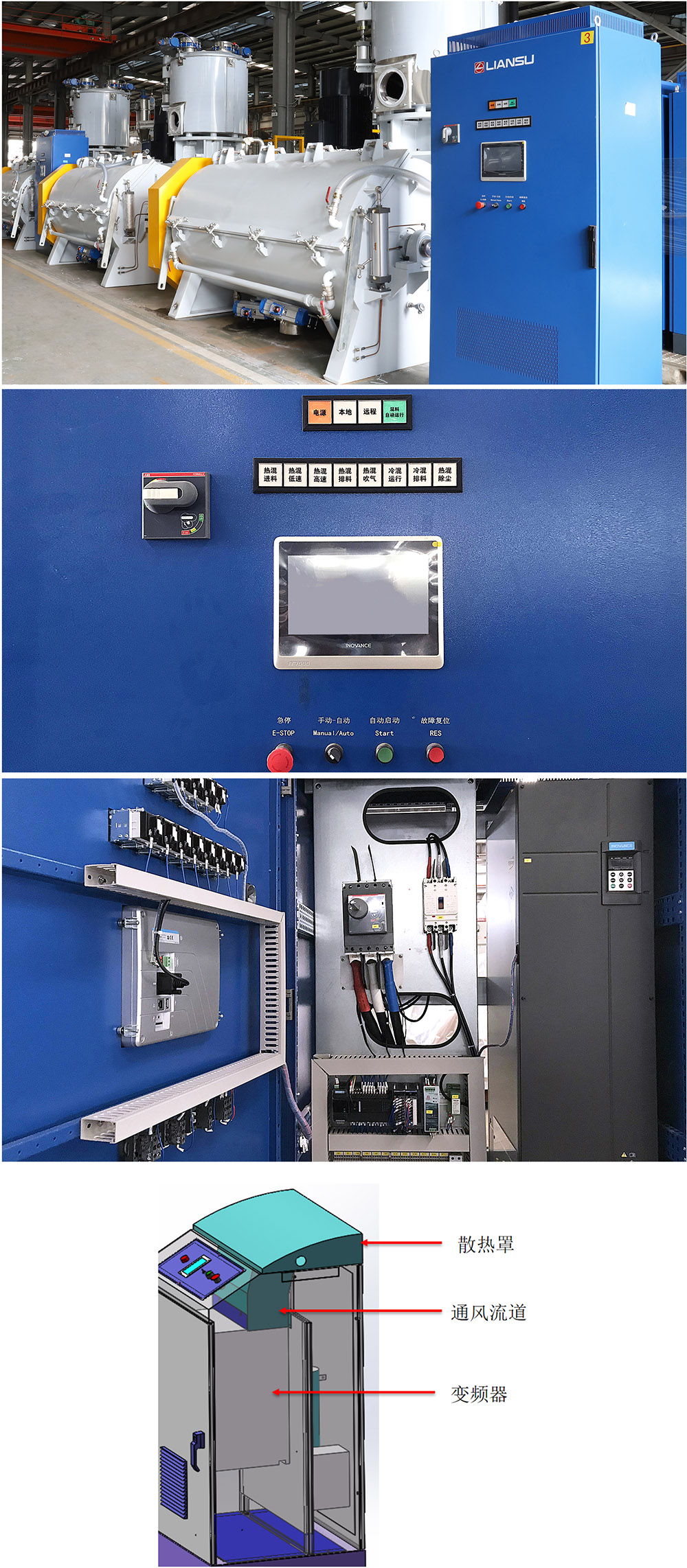

The unique electrical control system, special electrical control of stirring load

-The frequency converter adopts the installation mode are ‘ leading flow’ and ‘through the wall’ which can achieve the good heat dissipation effect.

-The high -speed mixer ‘s Frequency converter and PLC adopt modbus communication, and also adopt the control mode which close to the ‘constant current’ (through frequency converter or PLC control mode ), reduce mixing time to improve mixing efficiency as much as possible.

-The high-speed mixer’s frequency converter or PLC adopt the ‘ current stalled ‘ mode , with fast response, automatically adjust the mixing speed, control the blade maximum load output, more effectively protect the motor and inverter to deal with sudden large load impact.

-Control adopts 10’’ touch screen+PLC. The system is standard equipped with data collection of ‘energy consumption per ton’, which is convenient for customers to intuitively understand the energy consumption level of the equipment. The Ethernet communication interface is configured to facilitate data collection .